Inventio's software makes computer vision a simple and concrete tool for quality control in manufacturing. With Industrial App, companies adopt field-proven solutions that improve processes and products without integration or training complexity.

Inventio's AI modules recognize deviations and defects even if they were not provided during training. The system learns the normal process and automatically flags anything that deviates, ensuring constant and adaptive control.

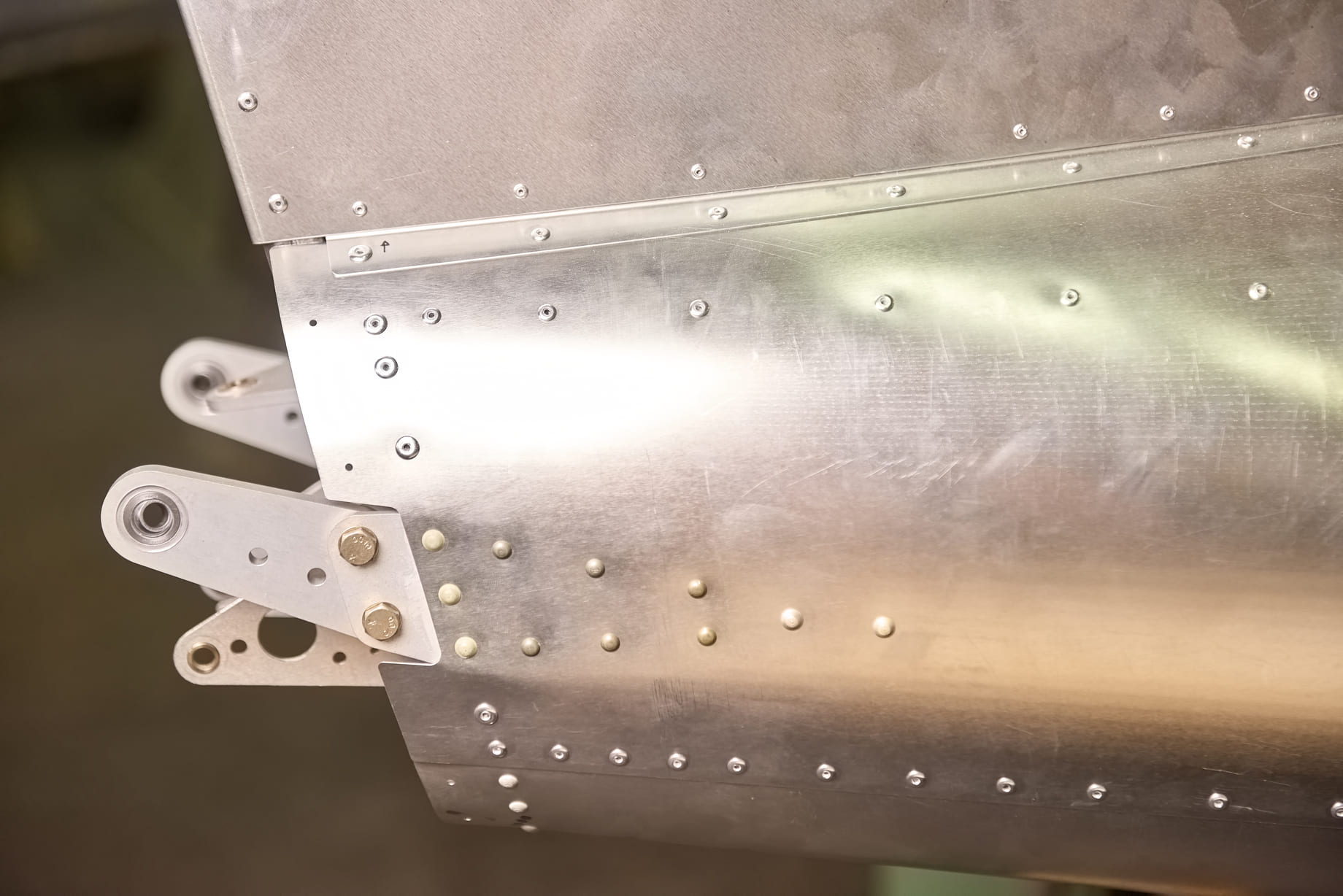

Detects scratches, dents and breaks even on reflective or moving surfaces.

Detects scratches, dents and breaks even on reflective or moving surfaces.

Detects deformations, bubbles or missing material on transparent or colored packages.

Detects deformations, bubbles or missing material on transparent or colored packages.

Checks film tension, folds and adhesion, ensuring uniform and sealed packaging.

Checks film tension, folds and adhesion, ensuring uniform and sealed packaging.

Analyzes weld beads and joints, identifying fusion defects or misalignments.

Analyzes weld beads and joints, identifying fusion defects or misalignments.

Detects microcracks, inclusions or color variations on continuous and high-speed materials.

Detects microcracks, inclusions or color variations on continuous and high-speed materials.

Automatically verifies that each element is correctly positioned or assembled.

Automatically verifies that each element is correctly positioned or assembled.

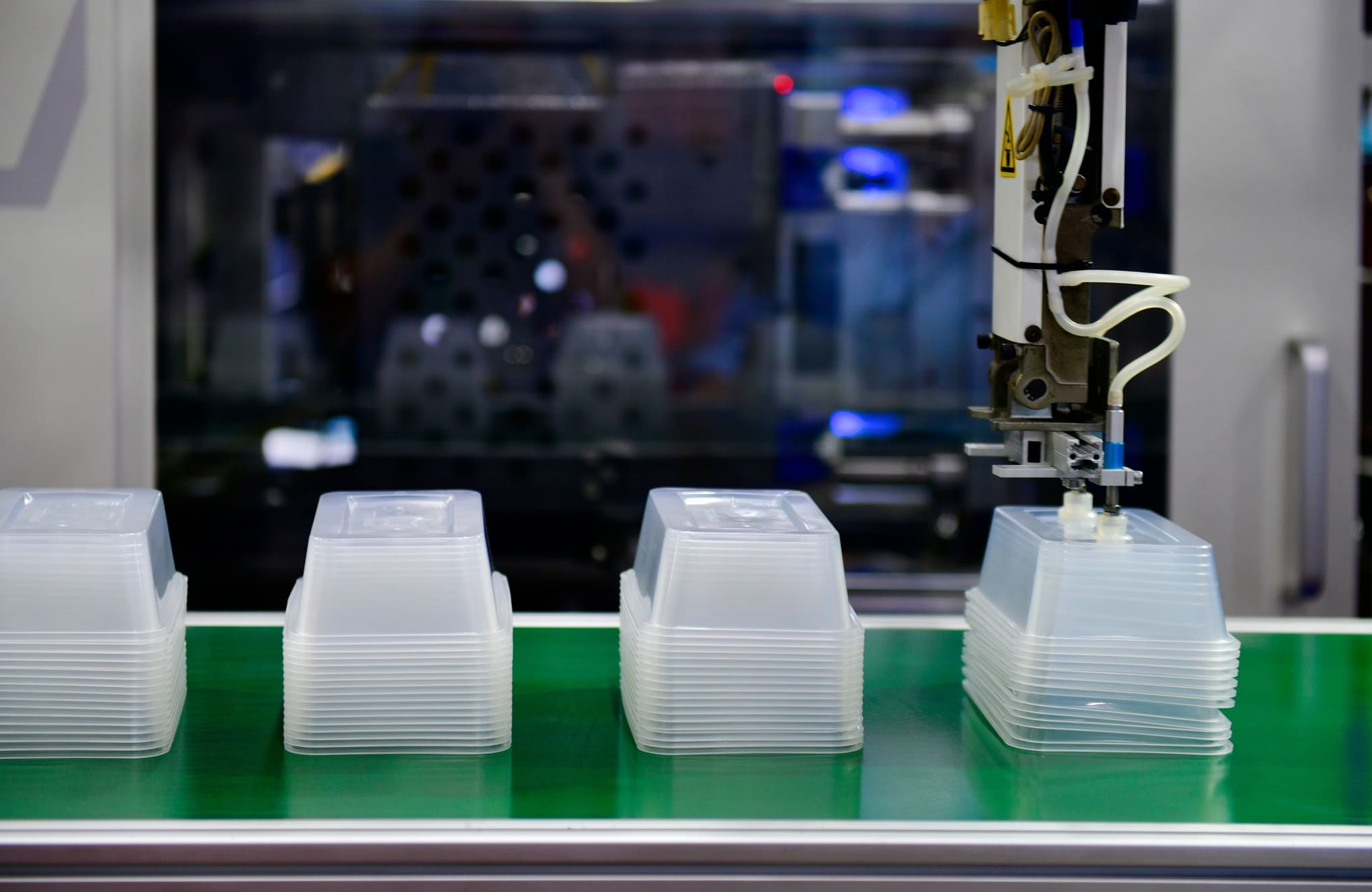

Inventio's AI automatically detects foreign bodies, scraps or jammed parts in molding and extrusion processes. Unlike traditional systems, it does not require complex training or defect images: it learns the normal behavior and signals any anomaly in real time, preventing damage and downtime.

Detects residual material or intrusions in the mold, preventing breaks and scrap.

Detects residual material or intrusions in the mold, preventing breaks and scrap.

Continuously identifies inclusions, impurities or thickness variations in the film.

Continuously identifies inclusions, impurities or thickness variations in the film.

Monitors the forming area to avoid closure on parts or scraps, protecting the mold and reducing downtime.

Monitors the forming area to avoid closure on parts or scraps, protecting the mold and reducing downtime.

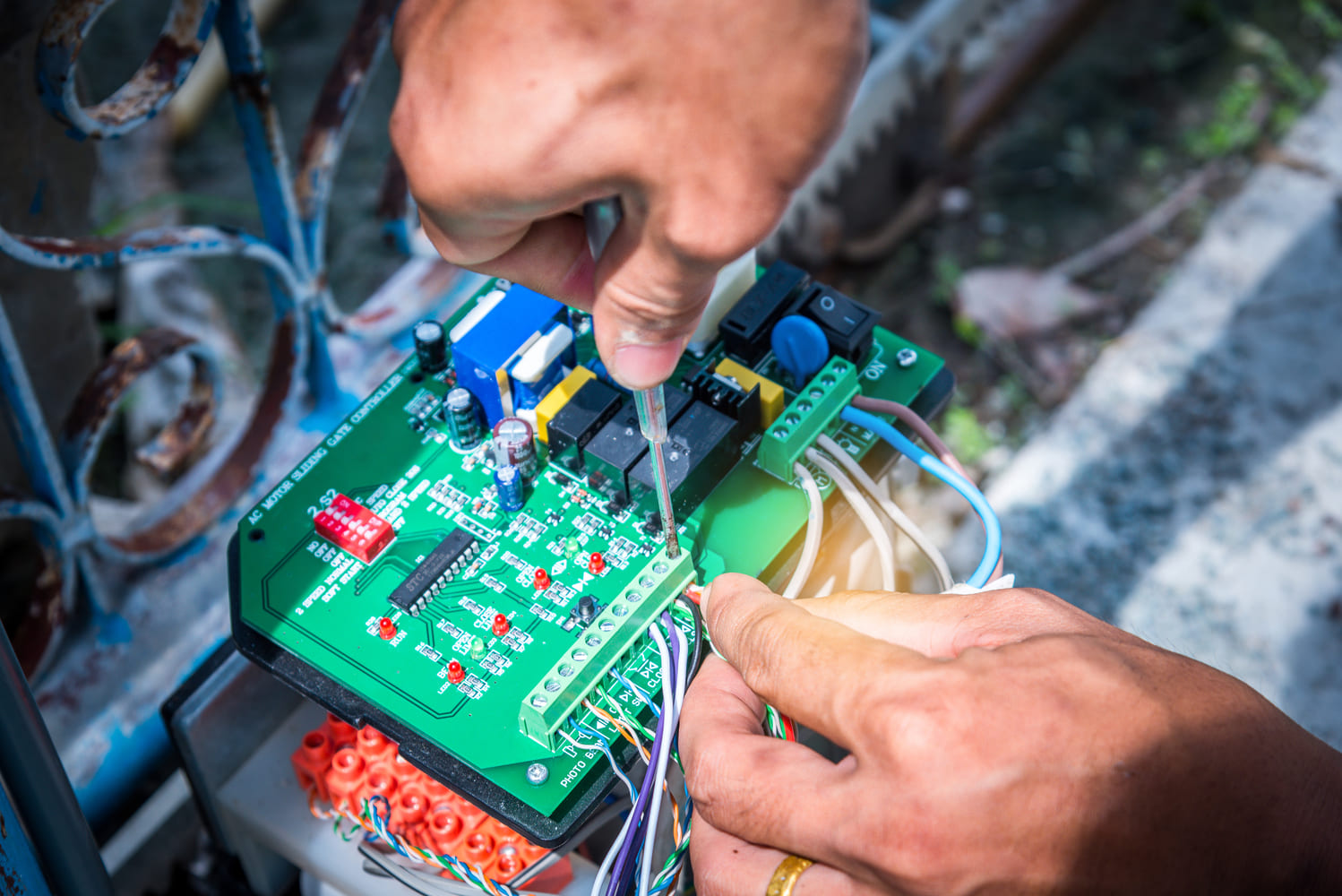

Inventio's solutions are a direct support tool for production workers. The AI automatically recognizes assembly phases, checks the correctness of operations and guides the operator in critical checks, without the need for complex programming or technical knowledge.

Confirms in real time the correct placement of boards, connectors and sensitive components, avoiding assembly errors.

Confirms in real time the correct placement of boards, connectors and sensitive components, avoiding assembly errors.

Assists the operator step-by-step, recognizing each completed phase and providing immediate visual feedback.

Assists the operator step-by-step, recognizing each completed phase and providing immediate visual feedback.

Automatically documents each verification, creating objective proof of quality and process traceability.

Automatically documents each verification, creating objective proof of quality and process traceability.

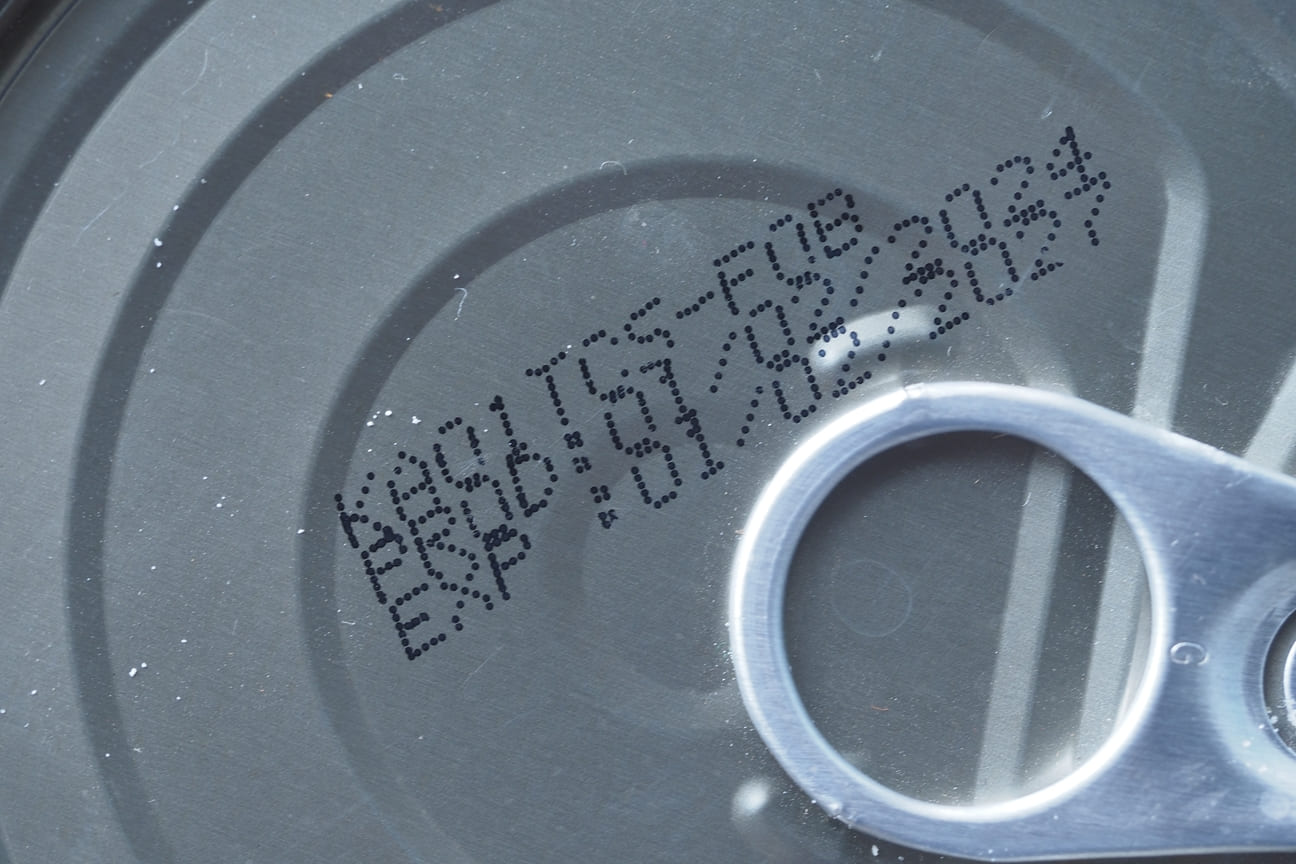

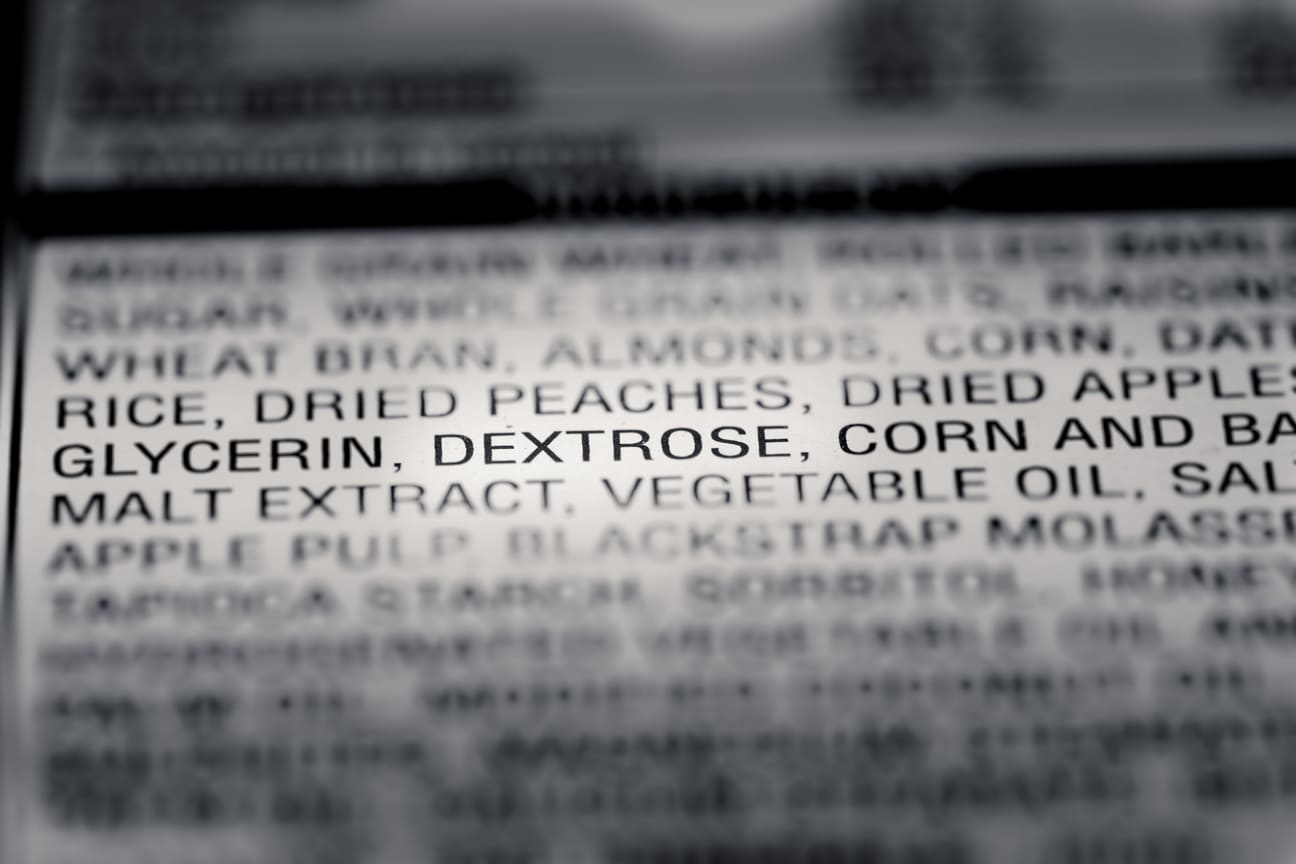

With Inventio, reading and verifying codes or labels becomes fast and reliable, even in difficult conditions. The system adapts to lighting, surfaces and print variants without requiring complex configurations or calibrations, ensuring full traceability on the line.

Automatically recognizes and records codes and dates on each package, even if partially damaged.

Automatically recognizes and records codes and dates on each package, even if partially damaged.

Decodes QR, Data Matrix and distorted serials, autonomously handling multiple formats and marking types.

Decodes QR, Data Matrix and distorted serials, autonomously handling multiple formats and marking types.

Checks position, graphics and legibility, ensuring conformity with the approved format and product compliance.

Checks position, graphics and legibility, ensuring conformity with the approved format and product compliance.

© 2025 Inventio.ai S.r.l.

•Via Torino 34, Fossano (CN) - 12045, Italy

•VAT: IT03927800049